Tools or dies are significant in the manufacturing process. They are so important that in the global market, tooling alone has a revenue of around 60 billion dollars last year. The increase in automation like CNC machining has also paved the way for simple tools that are faster to make.

When there is a demand for production, tooling usually takes longer to make. This long lead time can cause a delay in the entire production process. The solution is going for rapid tooling. To maximize the benefits of this process, you need to choose the right rapid tooling type for your part.

There are two types of rapid tooling: direct and indirect. Both have their own set of pros and cons and the choice will depend on the requirements. In this article, we will provide the general differences between these two so that you can make a sound decision on which type to choose.

Direct vs Indirect Tooling

There are plenty of differences between direct and indirect rapid tooling. Aside from its difference, another factor that would determine the right rapid tooling method is knowing when to use them.

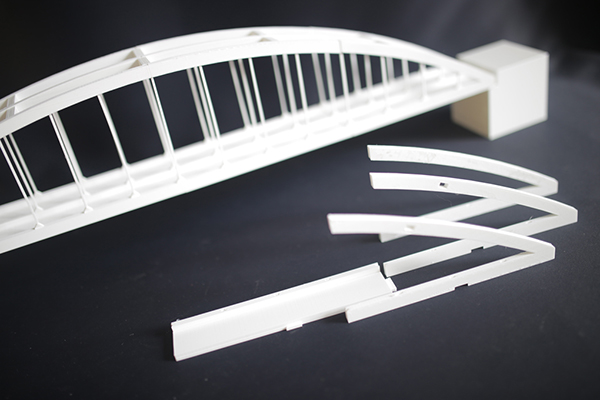

3D printed bridge prototypes*

3D printed bridge prototypes is from blog.zmorph3d.com

Direct Rapid Tooling

Many attempts have been made to develop a new manufacturing technique that would reduce the lead times that has been a huge obstacle in the industry in the past. One approach is called direct tooling and the best example for this would be CNC machining.

With the use of CAD digital file, the direct tooling machine can chip off part from a block in a subtractive process. The newest addition to the direct tooling process is 3D printing, which is an additive process. It builds a 3D shape object by adding the materials layer by layer.

Both processes are frequently used in manufacturing and took less time to produce. These are the pros and cons of using direct rapid tooling:

Pros

- Faster production

- It involves fewer steps and resources to make

- You can produce multiple prototypes

- Flexible

Cons

- Less durable

- Prone to minor errors

- Not suitable for complex designs

- Increase in cost

Indirect Rapid Tooling

The second approach to rapid tooling is indirect tooling where the tool is formed using an intermediate step known as the “master” model. The master is a 3D shape which can be copied multiple times. The process may be retrogressive but it was proven effective. It ensures that the tools are strong and robust for high-volume production.

Pros

- It makes durable tools

- More cost-effective

- You can create hard or soft tools depending on your requirement

- It produces tools with less discrepancies and variations

- You can use it to experiment with different materials

Cons

- It is more time-consuming

- Entails additional costs

- It needs high quality materials to improve its durability

- It does not fit simple designs and is more appropriate for complex designs

Key Takeaway

There you have it the major differences between direct and indirect tooling and its pros and cons. To choose the right rapid tooling solution, you need to evaluate your requirements and confer it with the pro-con list.