Why Do You Need the Services of a Rapid Prototyping Company?

Any product development in the world requires a prototype. The project may be of any size you can imagine, but nothing can go to production based on a concept. You need to make sure that your idea is functional and a rapid prototyping company can do that for you in a matter of moments.

Rapid prototyping as service costs money. Even if you are crafty enough to bring a proof of concept on your own, you need modern technology to make sure it works the way it’s supposed to. A part of your budget should be destined to the creation of a new prototype using automated means such as 3D printing.

One of the things that no one tells you is that if you only have a slight idea about your product. A rapid prototyping company has a team that can help you make your vision a reality for very little money and in a short time. Your rough ideas no longer need a separate designer since most of these companies have in-house design teams to create your prototype from scratch.

Rapid prototyping is suitable for entrepreneurs developing original equipment pieces. It works if they need a high-quality prototype in a narrow window of time to secure funding or to keep the costs of the budget at bay. You need these services because there has never been a better moment in the manufacturing industry to get ahead with your creations using these companies.

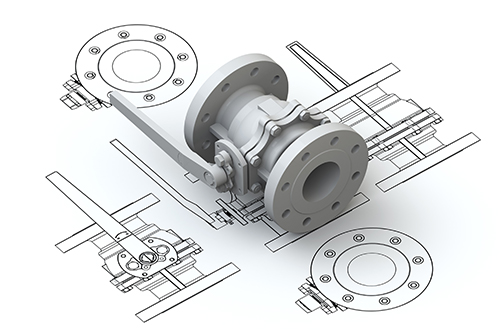

rapid prototype molds*

rapid prototype molds is from https://3dwalla.com

When Should You Use the Services of a Rapid Prototyping Company?

Rapid prototyping is the best fit to create plastic parts with precision. To achieve a good streak of usable products, you need to work with a team of people who knows what they are doing. Any rapid prototyping company worth their salt has a team of engineers and product developers to test your product and fix any issue on the go.

Think for a minute about all the products that require a perfect fit. It can be anything from protective gear for workers to a little moving part that goes inside a larger machine. Every single one of these products can be created using these services. If your project requires manufacturing, that’s when you should consult a company about a quote to get things done.

What the Actual Costs of Rapid Prototyping Services?

This is probably the trickiest question in the list because not all projects are meant to be developed by the same standards. If we consider complexities, a small piece no bigger than the sections of your hand can cost from $80 to $1,200. Small parts that require no post-production polishment sit on the low end of this spectrum. Components that require sanding or painting will cost a lot more.

What is the Most Popular Software used for Rapid Prototyping Projects?

The software program used to print prototypes is developed exclusively to work with the machines of the rapid prototype company of your choice. The developing software is another story since most companies use one of the following to create their CAD models: AutoCAD, Autodesk Inventor, Fusion360, Mastercam, Pro-E, or Pro/Engineer, or Solidworks.

Is it Possible to Create Rapid Prototypes Using Injection Molding Technology?

Injection molding is a process that can be used to create prototypes but also to mass produce any product. It’s the best expression of having your cake and eating it too. The most obvious advantage is the possibility to create a prototype, just the same way the product will be created. You only need to create a cavity mold that can process molten plastic to be injected and cooled to make a solid piece.

If you compare this method with 3D printing, you will realize how easily plastic injection molding can create higher-quality surface finishes. The amount of detail is extended to other features such as noticeable square holes, and living hinges. Other little bits that can be created using other manufacturing methods such as CNC machining. The only drawback of this method is the amount of time required to create the mold, as well as the overall cost of it.

After you are done with the stage, testing out the prototype should be a breeze. Remember to use it to evaluate everything regarding the specs of your project, such as the quality of the material used as well as the cosmetic finishes of the final product.

What You Should Look for in a Rapid Prototyping Company

Regardless of the location of your rapid prototyping company of choice, you need to pay attention to some details regarding your chosen service provider. Doing your homework on them will pay off for good on your end. Do an internet search on them, check for their reputation. Check if they have a consistent track record fulfilling the needs of their customers, see how quick they answer to your concerns. Make sure to check their prices against their competitors.