Experimentation is an important part of the research and construction procedure. However, it has historically presented difficulties when designers attempt to construct improvised representations which provide a sound foundation for a notion. Rapid tooling is an integral part of machining and other industries.

Throughout the former, prototyping needed virtually its same procedures, prices, manufacturing, and installation as the finished product, rendering them prohibitively expensive for many companies. On the other hand, injection molding has several benefits and uses that distinguish it from conventional tooling.

What is Rapid Tooling?

It’s helpful to understand the incident created before getting into the myriad studies and impacts linked with that. Rapid application development is a series of tools that are used to create a 3D larger version of a real component or item fast and effectively. 3D printing, also referred to as the application, is a logical and complementary approach since it does not need any equipment and effectively limits flexibility.

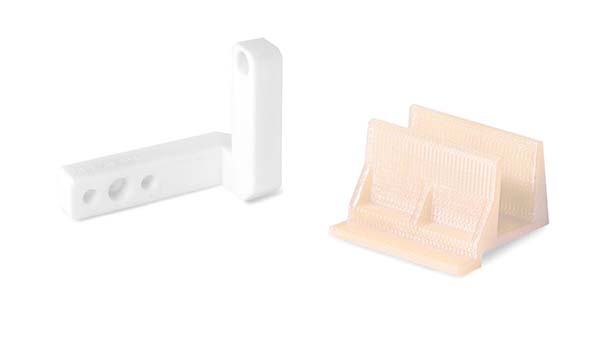

additive manufacturing parts*

additive manufacturing parts is from zare.it

Advantages:

- The order to rapidly investigate and realize thoughts. This schedule and budget savings help teams to transcend above simply seeing an item, making it much easier to comprehend its design elements.

- Applying recurring layouts and incorporating modifications allows for examinations. This incremental process serves as a guide for creating and fine-tuning the product.

- The capacity to examine and develop a treatment plan. The ability to decrease design defects with a limited quantity additive manufacturing run aids in the elimination of costly technical problems that may not be apparent when in the lead too quickly.

- Because setup and equipment aren’t required, you’ll conserve time and resources. Since the same technology is being used for structural parameters with various features and substances, the prices and time savings are significant.

Applications:

- Engineers can use characterized to evaluate both their concepts and the principles that underpin these. A tangible conception program is the best tool to investigate a notion, show its legitimacy to participants, and facilitate contact.

- Programmers may comprehend the nuances that create an important indicator of the completed article by using design solutions to test their authenticity before moving on with the next step. Before taking the item into entire production mode – another immeasurably greater expensive procedure — the fitment, appearance, maintainability, and functionality of the building can be checked.

- An additional aspect of rapid toolingis demonstrating that a functioning concept is also financially possible to build. Prototyping allows you to create a spectacular sample that strikes a good balance of usefulness and appearance while strongly impacted.

Conclusion:

For modest tasks, conventional tooling is frequently extremely expensive. When huge amounts of the item are not considered essential during circumstances, the customized quick prototyping solution provides a price, low-volume option. Rapid tooling is often used in corporate sectors for developing products or identifying design difficulties, and it provides a simple approach to mold. A mould made of aluminum or soft metal, a loaded mould foundation, and wrist components is all part of the quick manufacturing procedure.